MCC’s mobile factories turn rubble into interlocking bricks, producing up to 40 tonnes per shift to rapidly rebuild homes and critical infrastructure. Designed for global deployment, they meet local safety standards, train local teams, and enable resilient, sustainable reconstruction anywhere in the world.

A Simple and Flexible Solution

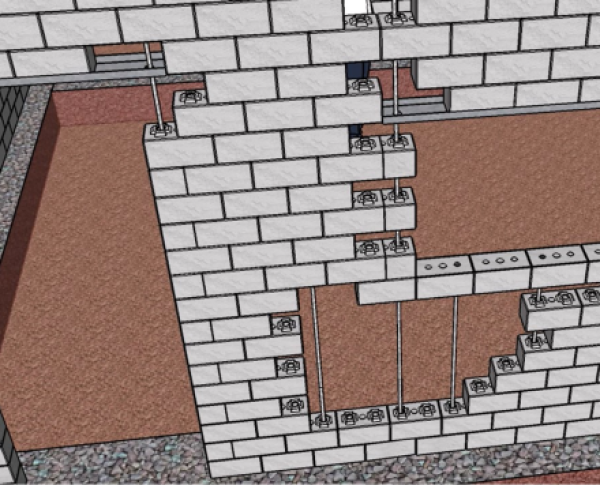

MCC Crisis Bricks employ simple technology that works with standard brick coursing height and length, and can be laid with unskilled labour due to their interlocking design. Walls can be built in a single day since no mortar is required in construction.

All the bricks – and the walls and pavers produced – are earthquake, fire and cyclone resistant, exhibiting superior performance to conventional brickwork.

Flexible Technology That Works, Long Term and Anywhere

Custom Requirements

MCC’s mobile factories offer custom sizes, shapes, and pavers tailored to local building methods and requirements, ensuring the right fit for any location.Onsite Adaptability

Bricks can be cut or molded to fit specific requirements, and rebar is grouted vertically through the bricks for added strength and durability.Flexible Options

MCC’s mobile factories produce bricks and pavers with adjustable thickness to align with local building practices. Flat-topped options are available for window sills and wall tops, offering versatile solutions for construction needs.

-

Debris is crushed with an MCC mill

Debris is crushed with an MCC mill -

The fine material is feed into our block factory

The fine material is feed into our block factory -

The fine material is feed into our block factory

The fine material is feed into our block factory

Brick and Paver Options

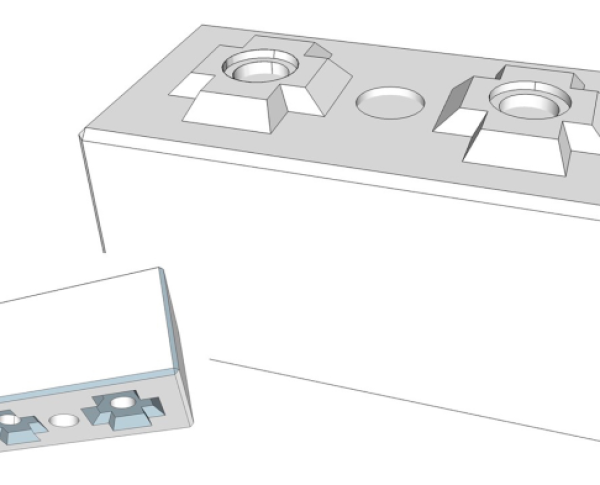

Modular brick options

- 300 by 100 mm interlocking modular brick, with 200 by 100 and 100 by 100 part bricks from the same mould

- 240 by 120 mm interlocking brick

- Each interlocking brick has a top mould change for flat topped bricks for window sills and top of walls.

Paver Options

- 240mm x 120mm, and 60mm or 80mm height

Tough and Elegant Solutions

Flexible Options

- Blocks easily made on a modern, small block making plant

- Thickness of blocks and pavers can be adjusted to suit local brick or block coursing

- Flat-topped options for window sills and wall tops

Onsite Adaptability

- Halves can be cut or made to suit

- Rebar grouted in place vertically through the bricks for strength

Custom Requirements

- Other sizes and shapes are available

- Mobile factories can have custom pavers and other block moulds

- Sizes suitable for the location and building methods for the location

Certification of Bricks and Walls

- Bricks are certified by a Structural Engineer signoff of LayGo TM Bricks

- LayGo Bricks provides technical support for MCC

- Structures are signed off by the Structural Engineer by location and associated risk zone

- LayGo Bricks provides mobile brick making machinery technology for MCC

Our Current Impact

The current focus of MCC is to send brick factories into Ukraine, rebuilding critical infrastructure, providing emergency shelter to those displaced by the ongoing war with Russia, by repurposing rubble, rubbish, and waste into modular bricks.

Each mobile factory requires AU $120,000 to be shipped to Ukraine, arriving ready to be fully operational with minimal local input. MCC will establish the initial rebuilding efforts in a relatively safe area north of Kyiv, and expand operations into other areas as needed, dependent on funding.

Rapid Response Construction

The mobile brick factory produces 30–40 tonnes of bricks per shift—enough in a week to build a school, clinic, or multiple homes. MCC also trains local staff and delivers globally within 12 weeks.Partnerships

MCC is seeking partnerships with NGO’s and Corporate entities to maximise the effectiveness of its own and/or partner rebuilding projects. To become an MCC affiliate contact us today with your idea.